Lingo 做线性规划 - Operation Management Applications

Reference: <An Introduction to Management Science Quantitative Approaches to Decision Making, Revised 13th Edition>

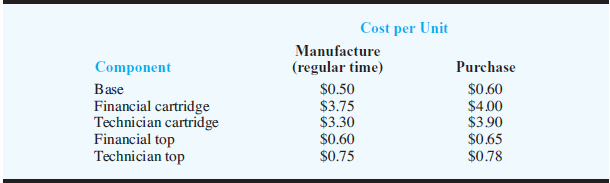

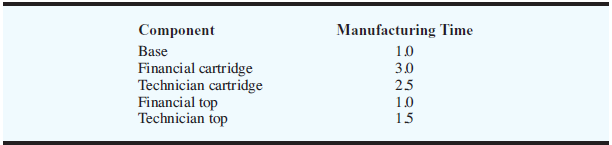

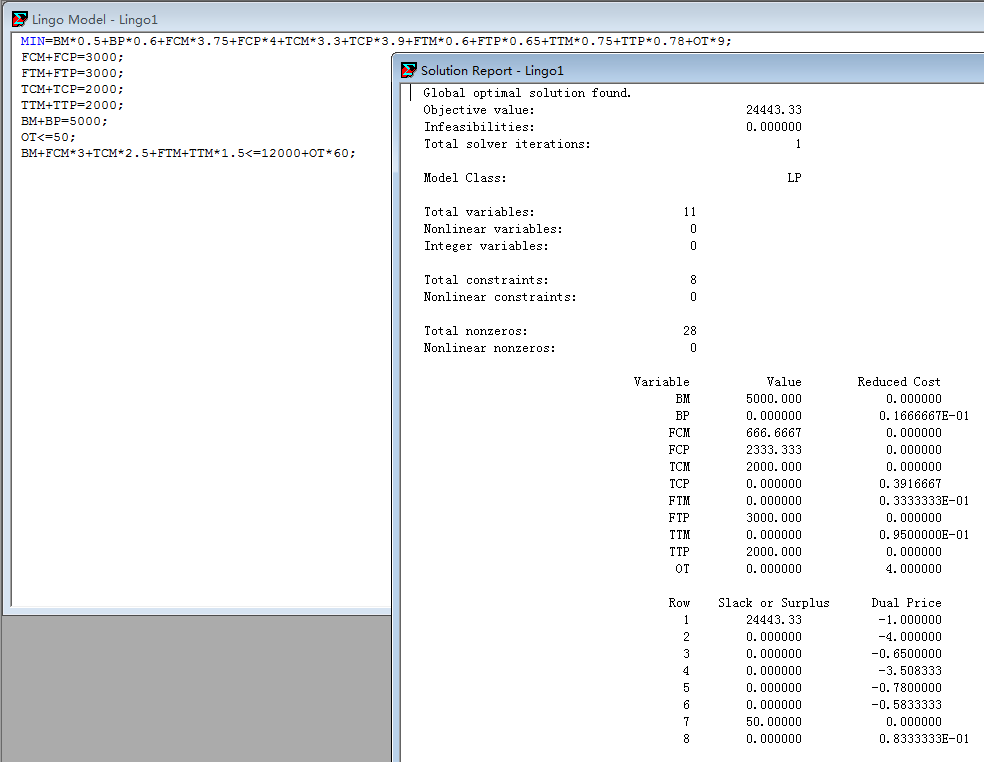

A Make-or-Buy Decision: Company forecasters indicate that 3000 Financial Manager calculators and 2000 Technician calculators will be needed. However, manufacturing capacity is limited. The company has 200 hours of regular manufacturing time and 50 hours of overtime that can be scheduled for the calculators. Overtime involves a premium at the additional cost of $9 per hour. Table 4.6 shows manufacturing times (in minutes) for the components.

A1:Build model as below:

BM = number of bases manufactured

BP = number of bases purchased

FCM = number of Financial cartridges manufactured

FCP = number of Financial cartridges purchased

TCM = number of Technician cartridges manufactured

TCP = number of Technician cartridges purchased

FTM = number of Financial tops manufactured

FTP = number of Financial tops purchased

TTM = number of Technician tops manufactured

TTP = number of Technician tops purchased

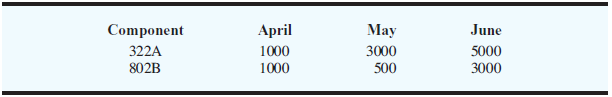

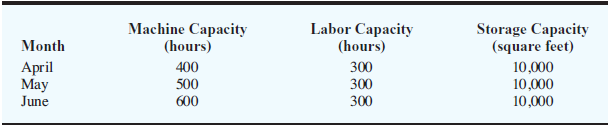

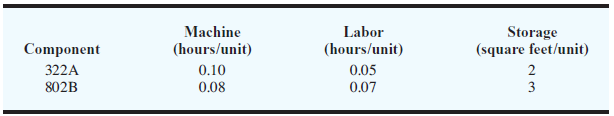

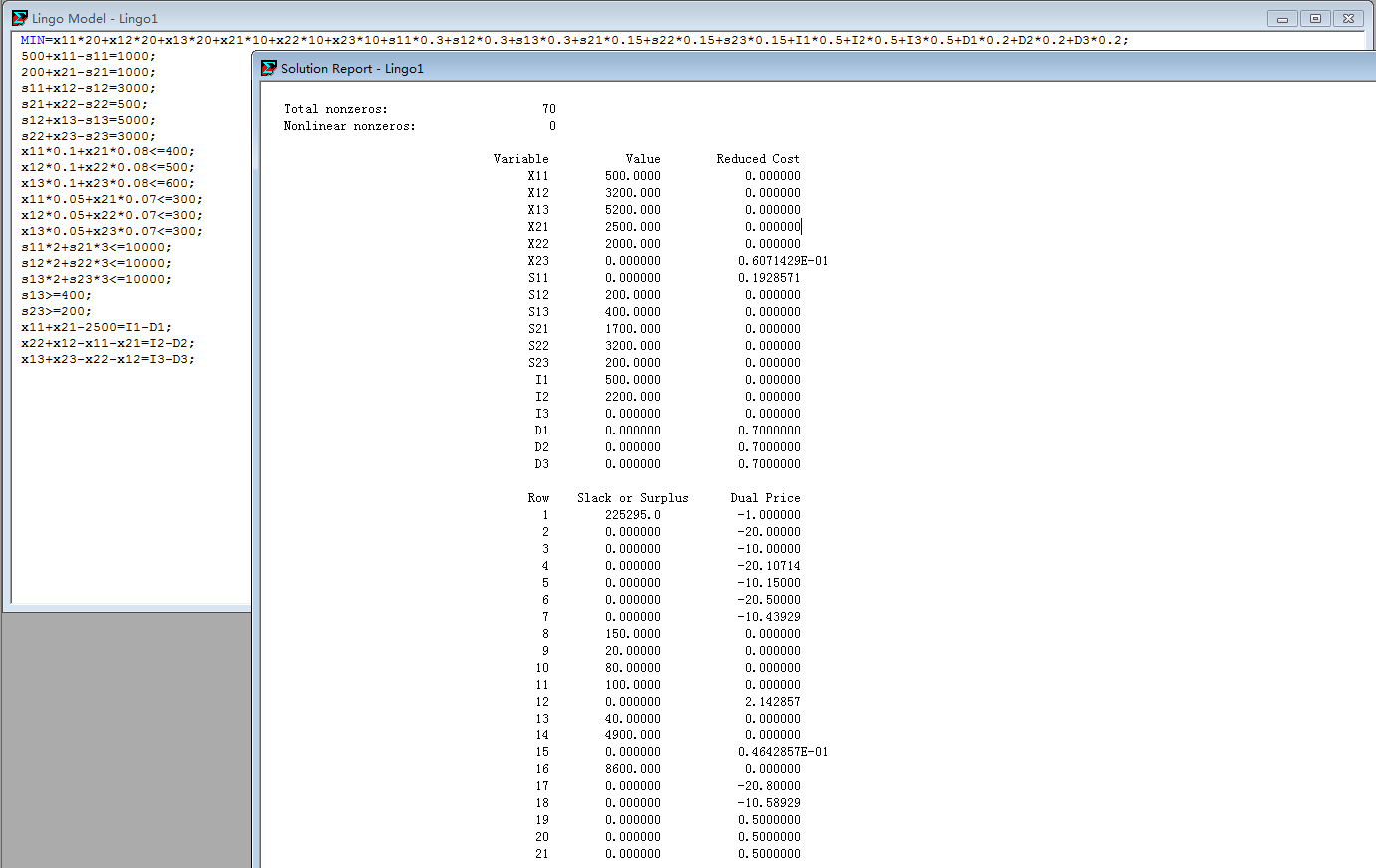

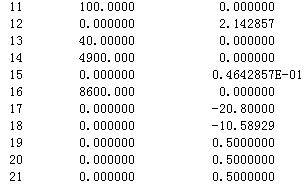

Production Scheduling: Let us consider the case of the Bollinger Electronics Company, which produces two different electronic components for a major airplane engine manufacturer. The airplane engine manufacturer notifies the Bollinger sales office each quarter of its monthly requirements for components for each of the next three months. The monthly requirements for the components may vary considerably, depending on the type of engine the airplane engine manufacturer is producing. The order shown in Table 4.7 has just been received for the next three-month period.

After the order is processed, a demand statement is sent to the production control department. The production control department must then develop a three-month production plan for the components. In arriving at the desired schedule, the production manager will want to identify the following:

1. Total production cost

2. Inventory holding cost

3. Change-in-production-level costs

To develop the model, we let xim denote the production volume in units for product i in month m. Here i =1, 2, and m =1, 2, 3; i =1 refers to component 322A, i =2 refers to component 802B, m 1 refers to April, m =2 refers to May, and m=3 refers to June. The purpose of the double subscript is to provide a more descriptive notation. We could simply use x6 to represent the number of units of product 2 produced in month 3, but x23 is more descriptive, identifying directly the product and month represented by the variable.

If component 322A costs $20 per unit produced and component 802B costs $10 per unit produced. Bollinger determined that on a monthly basis inventory holding costs are 1.5% of the cost of the product;Bollinger estimates that the cost associated with increasing the production level for any month is $0.50 per unit increase. A similar cost associated with decreasing the production level for any month is $0.20 per unit.

Suppose that the inventories at the beginning of the three-month scheduling period were 500 units for component 322A and 200 units for component 802B.

company specifies a minimum inventory level at the end of the three-month period of at least 400 units of component 322A and at least 200 units of component 802B.

Suppose that the production levels for March, the month before the start of the current production scheduling period, had been 1500 units of component 322A and 1000 units of component 802B

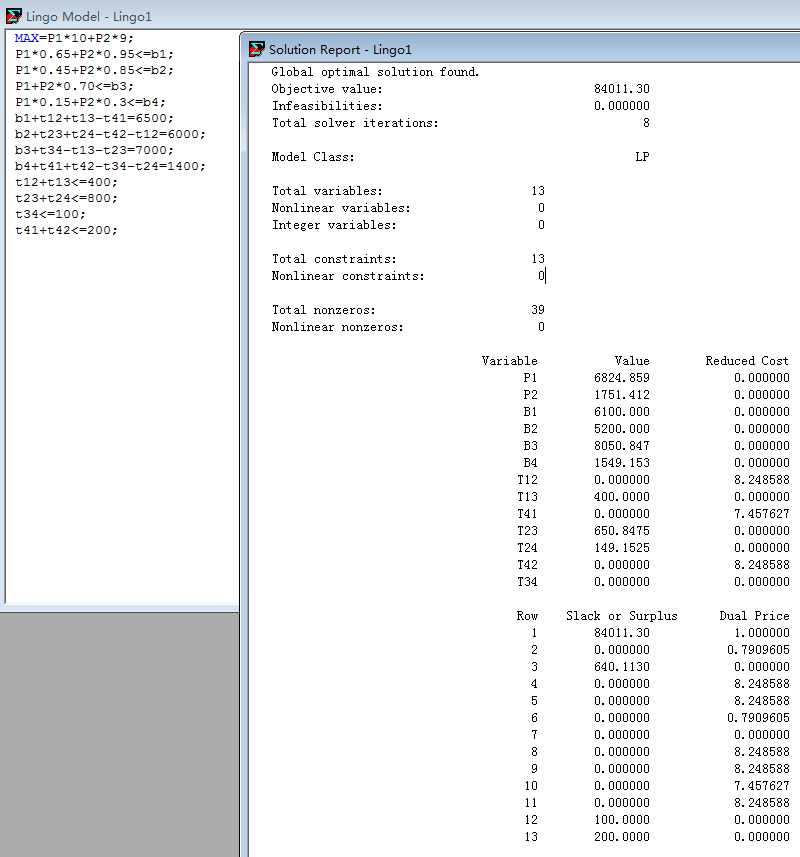

Workforce Assignment:McCormick Manufacturing Company produces two products with contributions to profit per unit of $10 and $9, respectively. The labor requirements per unit produced and

the total hours of labor available from personnel assigned to each of four departments are shown in Table 4.11.

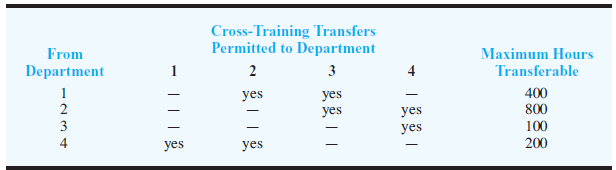

Suppose that McCormick has a cross-training program that enables some employees to be transferred between departments. By taking advantage of the cross-training skills, a limited number of employees and labor-hours may be transferred from one department to another. For example, suppose that the cross-training permits transfers as shown in Table 4.12. Row 1 of this table shows that some employees assigned to department 1 have cross-training skills that permit them to be transferred to department 2 or 3. The right-hand column shows that, for the current production planning period, a maximum of 400 hours can be transferred from department 1. Similar cross-training transfer capabilities and capacities are shown for departments 2, 3, and 4.

A:build model as below

P1 = units of product 1

P2 = units of product 2

bi =the labor-hours allocated to department i for i = 1, 2, 3, and 4

tij =the labor-hours transferred from department i to department j

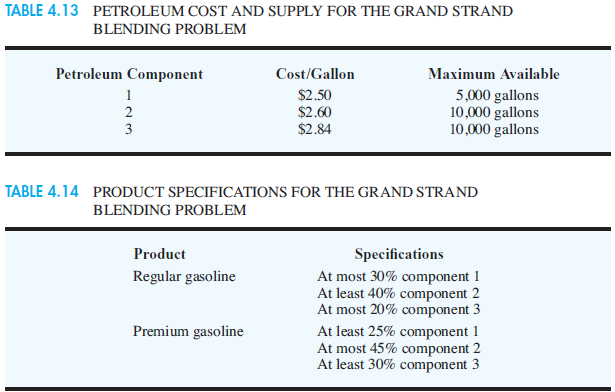

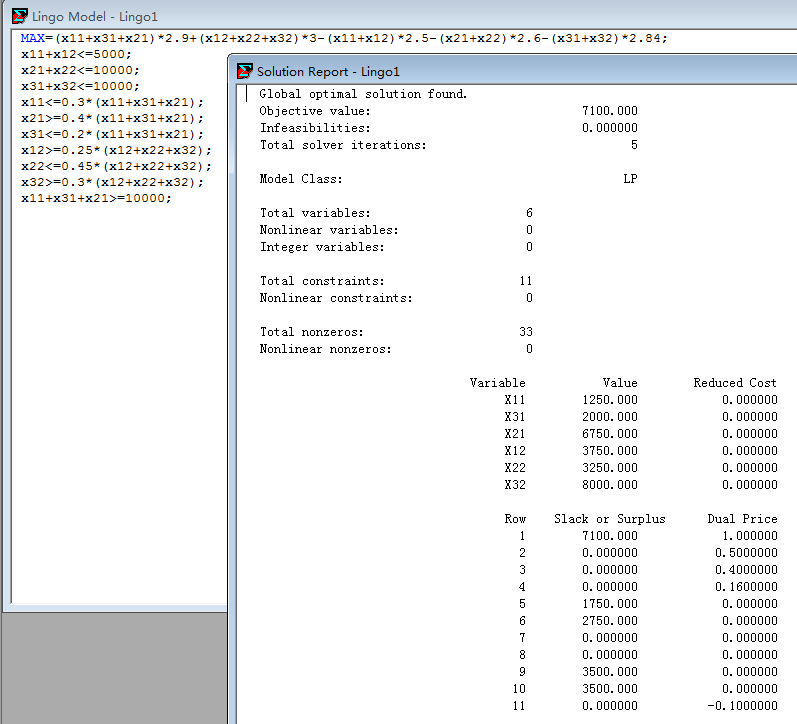

Blending Problems:Data available show that regular gasoline can be sold for $2.90 per gallon and premium gasoline for $3.00 per gallon. For the current production planning period, Grand Strand can obtain the three petroleum components at the cost per gallon and in the quantities shown in Table Product specifications for the regular and premium gasolines restrict the amounts of each component that can be used in each gasoline product. Table 4.14 lists the product specifications. Current commitments to distributors require Grand Strand to produce at least 10,000 gallons of regular gasoline.

The Grand Strand blending problem is to determine how many gallons of each component should be used in the regular gasoline blend and how many should be used in the premium gasoline blend. The optimal blending solution should maximize the firm’s profit,subject to the constraints on the available petroleum supplies shown in Table 4.13, the product specifications shown in Table 4.14, and the required 10,000 gallons of regular gasoline.

xij =gallons of component i used in gasoline j, where i = 1, 2, or 3 for components 1, 2, or 3, and j = 1 if regular or j = 2 if premium

Lingo 做线性规划 - Operation Management Applications的更多相关文章

- Lingo 做线性规划 - Revenue Management

Reference: <An Introduction to Management Science Quantitative Approaches to Decision Making, Rev ...

- Lingo 做线性规划 - Financial Applications

Reference: <An Introduction to Management Science Quantitative Approaches to Decision Making, Rev ...

- Lingo 做线性规划 - Marketing Applications

Reference: <An Introduction to Management Science Quantitative Approaches to Decision Making, Rev ...

- Lingo 做线性规划 - Game Thoery

Reference: <An Introduction to Management Science Quantitative Approaches to Decision Making, Rev ...

- Lingo 做线性规划 - Asset allocation and Portfolio models

Reference: <An Introduction to Management Science Quantitative Approaches to Decision Making, Rev ...

- Lingo 做线性规划 - DEA

Reference: <An Introduction to Management Science Quantitative Approaches to Decision Making, Rev ...

- Lingo求解线性规划案例4——下料问题

凯鲁嘎吉 - 博客园 http://www.cnblogs.com/kailugaji/ 造纸厂接到定单,所需卷纸的宽度和长度如表 卷纸的宽度 长度 5 7 9 10000 30000 20000 工 ...

- Lingo求解线性规划案例1——生产计划问题

凯鲁嘎吉 - 博客园 http://www.cnblogs.com/kailugaji/ 说明: Lingo版本: 某工厂明年根据合同,每个季度末 ...

- Lingo求解线性规划案例3——混料问题

凯鲁嘎吉 - 博客园 http://www.cnblogs.com/kailugaji/ 某糖果厂用原料A.B和C按不向比率混合加工而成甲.乙.丙三种糖果(假设混合加工中不损耗原料).原料A.B.C ...

随机推荐

- 2018.07.10 NOIP模拟 sort(单调队列)

Sort 题目背景 SOURCE:NOIP2016-RZZ-4 T1 题目描述 给你一个长度为 n 的排列,小W每次可以选择一个数,做以下操作: 不断把这个数与它右边的数交换. 当它右边没有数,或它右 ...

- SQL查询优化的一些建议

使用批量查询,而不是N次循环查询! 重复的数据,不要重复获取: 根据需要,按需要获取表字段,而不是SELECT *: 针对频繁的搜索字段,建立必要的索引,以加快查询速度: 使用关联查询,而不是粗暴地类 ...

- bootstrap-treeview的 简单使用

理论:http://blog.csdn.net/babyxue/article/details/73835444 插依赖Bootstrap 和jQuery <link href="~/ ...

- POJ 3621 Sightseeing Cows (bellman-Ford + 01分数规划)

题意:给出 n 个点 m 条有向边,要求选出一个环,使得这上面 点权和/边权和 最大. 析:同样转成是01分数规划的形式,F / L 要这个值最大,也就是 G(r) = F - L * r 这个值为0 ...

- RESTful架构概念

本文转载自:http://www.ruanyifeng.com/blog/2011/09/restful.html 越来越多的人开始意识到,网站即软件,而且是一种新型的软件. 这种"互联网软 ...

- 01-html和head介绍

一.web标准 web准备介绍: w3c:万维网联盟组织,用来制定web标准的机构(组织) web标准:制作网页遵循的规范 web准备规范的分类:结构标准.表现标准.行为标准. 结构:html.表示: ...

- 编译hbase-1.2.3源代码

目录 目录 1 1. 约定 1 2. 安装jdk 1 3. 安装maven 1 4. 网络配置 2 4.1. eclipse 3 4.2. maven 3 5. 从hbase官网下载源代码包: 4 6 ...

- hdu 5024 最长的L型

http://acm.hdu.edu.cn/showproblem.php?pid=5024 找到一个最长的L型,L可以是斜着的 简单的模拟 #include <cstdio> #incl ...

- date(): It is not safe to rely on the system’s timezone settings.

在执行php脚本时出现的错误: date(): It is not safe to rely on the system’s timezone settings.You are *required* ...

- Spring注解使用和与配置文件的关系

Spring注解使用和与配置文件的关系 1 注解概述与容器管理机制 Spring 2.5 中除了提供 @Component 注释外,还定义了几个拥有特殊语义的注释,它们分别是:@Repositor ...