High Voltage Boost Supply

http://learn.adafruit.com/ice-tube-clock-kit/design

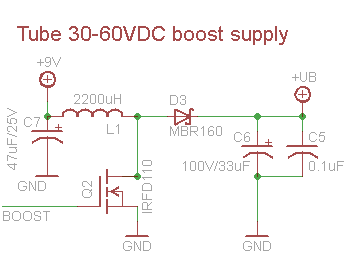

Tubes such as VFDs, Nixies, Decatrons, etc require high voltage to light the gas in the tube. For nixies, this iabout 170VDC. VFDs aren't as bad they only need about 30-50VDC. In order to reduce cost, we use the microconrtoller to make a boost converter and avoid paying $5 for a seperate chip. We can do this because we don't need a precision output and the current draw is mostly constant. The boost regulator is run open-loop there is no feedback resistor divider as it isn't necessary as long as the input voltage is within a reasonable range.

The boost circuit works by connecting the power inductor L1 to ground that current can flow through it by turning on Q2. After a little bit of time, we disconnect the from ground (by turning off Q2) this means that there is no longer a path for the current in L1 to flow to ground. When this happens, the voltage across the inductor increases (this is the electric property of inductors) and charges up C6 . When the voltage increases to the level we want it to be (30V+) we turn on Q2 again which allows the current in L1 to flow back to ground. If we do this fast enough, and C6 large enough, the voltage on C6 is smoothed out and we get a nice steady high voltage.

The timing of turning off/on Q2 allows us to modify the output voltage. Normally there is a feedback resistor to the microcontroller but it is not here because we are running it open-loop. To drive Q2 we use the PWM output from the microcontroller and adjust the duty cycle to vary brightness.

- The voltage in is nominally 9 to 12VDC

- The current draw for the IV-18 tubes is about 8mA per digit and 11mA for the grid. Remember, though, that we only light up one digit at a time! So we need about 20mA total (we also meaured this in-circuit to verify)

- The voltage output is going to be between 30V-50V (its really much too bright after that point)

- The PWM output speed of the microcontroller is F_CPU / 256 = 8 MHz / 256 = 31.25KHz (period of 32 useconds)

With this information we can calculate the inductor size and capacity!

The optimal transfer between Vin and Vout is:

Vo/Vi = 1 / (1-D) where D is the duty cycle.

Solving for D = 1 - (Vi/Vo) and plugging in numbers:

For Vo = 50V and Vi = 9V, D = 82% (maximum)

For Vo = 30V and Vi = 12V D = 60% (minimum)

So the duty range will be between 60% and 82%. That would correspond to between ~150 and 220 out of 256, but note that when the PWM signal islow the switch is on so we need to invert that to a range of about 36 to 106 (in the code we actually use about 20 to 90).

OK so our PWM range is good, we just want to keep it between around 10% and 90% which we do.

Next, we need to make sure that the inductor continuously dumps current into C6 the entire time Q2 is off (continuous conduction mode). This is dependant on a lot of variables:

D*T*Vin/(2*L) < iout/(1-D)

Note that T is period time and is = 1/frequency. Solving for L, we choose the lowest duty cycle which will give us the upper bound for the inductor:

D*Vin * (1-D) / (freq * 2 * Iout ) < L

D = 60% (0.6)

iout = 20mA (0.02 Amp)

Vin = 12V nominal

1/T = freq = 31250 HzL > 0.6 * 12 * (1 - 0.6) / (31250* 2 * 0.02)

L > 2304 uH

This is our upper limit, so lets just say L = 2200uH (a standard value). Note that for 9V->60 we need L > 918uH which is our lower bound and our average case is a duty cycle of about 70% which is 1500uH.

We also want to make sure that we have a enough current capacity, so lets calculate the maximum current that builds up in the inductor. We now have to pick this for the -smallest- inductor, in the case of 9V boosting to 50V, an 82% duty cycle.

Ipk = (Vin * D)/(f * L)

Ipk = (9 * 0.82)/(31250 * .001) = 0.24 Amp

So! We want to make sure our inductor is > 2200 uH and will not saturate below 0.24 A.

The important thing to note here is that, for a given package (size) of inductor, the higher the inductance the lower the current capability.

Since this is a through-hole kit, we have to stick with a radial/axial inductor.

Searching Mouser for power inductors, we find the RLB9012 family (datasheet) which is the same type used in the mintyboost. This is a good inductor family, lets check out the range.

t looks like we're good to go with this group of inductors as the max current capacity of the 2200uH is well above our minimum 0.25 Any value higher than that will be OK as the Ipk will fall faster than the IDCmax

In reality, you don't need such high inductances because our system is not running on a battery and doesn't require a great power supply with low ripple and good efficiency. Inducances 270uH and lower worked just fine, the converter is operating in discontinuous mode which is not as efficient. Its also not as easy to calculate the precise specifications. Luckily this is a very indiscriminate tube and is cool with ripple and voltage fluctuations.

The diode is a schottky type, and needs to have a breakdown voltage larger than the maximum boost voltage (in this case 60V) we're usingMBR160 with 60V breakdown.

One way to improve the design to reduce the size and power requirements of the inductor is to increase the frequency. Doubling the frequency halves the required inductance and current requirements of the inductor!

I have a nice little calculator if you want to design your own basic boost converter

Thanks tons to Riad at jfet.org for the idea and calculations! (He has some great clock designs, so check them out)

For more information on boost converters see this article on wikipedia.

http://en.wikipedia.org/wiki/Boost_converter

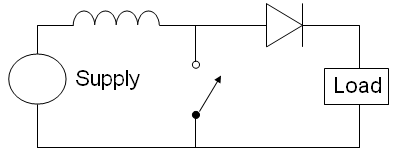

A boost converter (step-up converter) is a DC-to-DC power converter with an output voltage greater than its input voltage. It is a class of switched-mode power supply (SMPS) containing at least two semiconductor switches (a diode and a transistor) and at least one energy storage element, a capacitor, inductor, or the two in combination. Filters made of capacitors (sometimes in combination with inductors) are normally added to the output of the converter to reduce output voltage ripple.

The basic schematic of a boost converter. The switch is typically a MOSFET, IGBT, or BJT.

http://learn.adafruit.com/diy-boost-calc

For many small projects, its cheaper and easier to DIY a boost converter than to buy a specialty chip. DIY converters are usually not as efficient but they're quick & cheap!

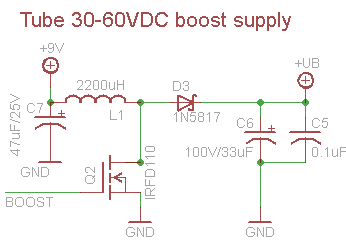

The above schematic section shows how I designed a 30-60V vacuum fluorescent tube display driven from a microcontroller pin.

Tubes such as VFDs, Nixies, Decatrons, etc require high voltage to light the gas in the tube. In order to reduce cost, we use a microconrtoller to make a boost converter and avoid paying $5 for a seperate chip. We can do this because we don't need a precision output and the current draw is mostly constant. The boost regulator is run open-loop there is no feedback resistor divider as it isn't necessary as long as the input voltage is within a reasonable range

The microcontroller runs at 8MHz so the 8-bit PWM output is 31250 Hz. The inductor and output capacitor is calculated below. The diode is a standard Schottkey type, but make sure you specify one that can handle the full voltage difference and peak current. The switch just has to be able to handle the max voltage plus some for safety. Note that this design is meant for 'static' output currents, not for variable current draw designs. There is no feedback and its very approximate! This is not for precision electronics!

The boost circuit works by connecting the power inductor L1 to ground that current can flow through it by turning on Q2. After a little bit of time, we disconnect the inductor from ground (by turning off Q2) this means that there is no longer a path for the current in L1 to flow to ground. When this happens, the voltage across the inductor increases (this is the electric property of inductors) and charges up C6 . When the voltage increases to the level we want it to be (30V+) we turn on Q2 again which allows the current in L1 to flow back to ground. If we do this fast enough, and C6 large enough, the voltage on C6 is smoothed out and we get a nice steady high voltage

The timing of turning off/on Q2 allows us to modify the output voltage. Normally there is a feedback resistor to the microcontroller but it is not here because we are running it open-loop. To drive Q2we use the PWM output from the microcontroller and adjust the duty cycle to vary brightness.

These sorts of designs can be easily made with a 555, once you have the PWM output, connect it up toQ2!

http://learn.adafruit.com/diy-boost-calc/the-calculator

http://learn.adafruit.com/downloads/pdf/diy-boost-calc.pdf

High Voltage Boost Supply的更多相关文章

- OpAmp Voltage Follower/Regulator

LDO Regulator High accuracy voltage regulator Vout = 2.5V * (1 + ( 5.6 / 6.8 ) ) = 4.55V Recently th ...

- OBD Experts OBD II Software OBD II Protocol Stack

http://www.obdexperts.co.uk/stack.html OBD II Software OBD Experts can provide you with ready to use ...

- 【转】linux设备驱动之MMC SD卡——核心层简单分析

原文网址:http://blog.chinaunix.net/uid-28685940-id-3889878.html /*************************************** ...

- An Isolated DAC Using PWM Output

An Isolated DAC Using PWM Output Arduino‘s (ATmega328P) PWM outputs via analogWrite can be convenien ...

- RF layout check list

Analog-digital circuit 1. Insure C36 and C33 placed next to each other to avoid open stubs 2. Keep U ...

- Use two picogate devices for bidirectional level-shifting

In new mixed-voltage systems, it is often necessary to level-shift a control signal from a high leve ...

- PatentTips - Integrated circuit well bias circuitry

1. Field of the Invention This invention relates in general to an integrated circuit and more specif ...

- Get just enough boost voltage - current-mirror circuit - VOUT tracks VIN varies

Adding a current-mirror circuit to a typical boost circuit allows you to select the amount of boost ...

- BOOST Converter Analog/Digital Adjusted Output Voltage TPS61045 MAX1932

DIGITALLY ADJUSTABLE BOOST CONVERTER The TPS61045 is a high frequency boost converter with digitally ...

随机推荐

- jQuery之字体大小的设置

先获取字体大小,进行处理. 再将修改的值保存. slice() 方法可从已有的数组中返回选定的元素.arrayObject.slice(start,end).start 必需.规定从何处开始选 ...

- bootstrap File Input 多文件上传插件使用记录(二)删除原文件

在上一篇文章中,主要介绍了file input插件的初始化和多文件同步上传到服务器的相关配置等.这篇主要介绍file input插件的编辑等. 使用场景: 在后台管理框架中,一条数据中包含不固定的多张 ...

- centos7.2下caffe的安装及编译

1.前期准备 安装依赖 sudo yum install protobuf-devel leveldb-devel snappy-devel opencv-devel boost-devel hdf5 ...

- Android仿苹果版QQ下拉刷新实现(一) ——打造简单平滑的通用下拉刷新控件

前言: 忙完了结婚乐APP的开发,终于可以花一定的时间放在博客上了.好了,废话不多说,今天我们要带来的效果是苹果版本的QQ下拉刷新.首先看一下目标效果以及demo效果: 因为此效果实现的步骤 ...

- 毕设demo写好

2015年1月20日 14:41:47 阶段性暂停!! 把运行结果截图给了老师,老师说先整理下文档,然后下学期来了再部署到服务器上. 那么,下学期来了,估计也要把Epm和CR1000什么的搞好了. 先 ...

- Fedora下Eclipse/MyEclipse崩溃的解决方案

Fedora19下使用myeclipse2013时,打开不到一分钟就异常关闭. 默认在home目录下生成一个log文件,里面显示的错误信息,说是libsoup.so文件导致出错.第一个想法是删除这个文 ...

- Struts DispatchAction Example

The DispatchAction class (org.apache.struts.actions.DispatchAction) provides a way to group all rela ...

- 【洛谷】P2000 拯救世界

题解 小迪的blog : https://www.cnblogs.com/RabbitHu/p/9178645.html 请大家点推荐并在sigongzi的评论下面点支持谢谢! 掌握了小迪生成函数的有 ...

- ava包(package)的命名规范,java中package命名规则

Java的包名都有小写单词组成,类名首字母大写:包的路径符合所开发的 系统模块的 定义,比如生产对生产,物资对物资,基础类对基础类.以便看了包名就明白是哪个模块,从而直接到对应包里找相应的实现. 由于 ...

- git推送本地仓库到github

总结一下,方便后人,也方便自己查阅.直接写步骤 一.本地创建一个文件夹,在里面写项目的文件(* .php/*.js.....). git本地操作: 1 . cd /path/to/project ...